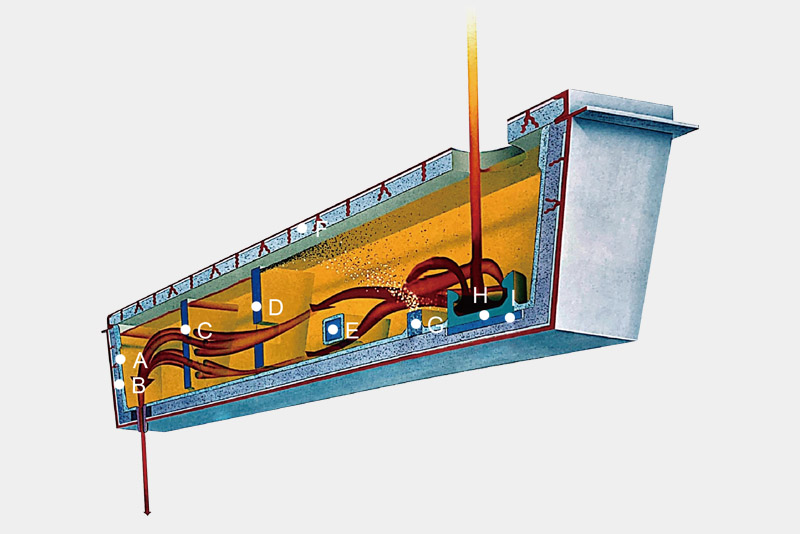

Tundish material unshaped refractory

Production Process:

1、Spray mass for tundish: using magnesia as the main raw material, adding water reducing agent, binder, anti-explosive agent, etc. by mixing.

2、Dry material for tundish: using magnesia and composite materials as the main raw materials, adding a variety of binders and mixing.

3、Coating mass for tundish: using magnesia and forsterite as the main raw materials, adding binder, dispersant, anti-explosive agent, etc. by mixing..

4、Castable for tundish permanent lining: It is made by mixing bauxite and composite materials as main raw materials. adding composite water reducing agent and binder.

Main application:

1、Spray mass for tundish:used for tundish work lining spray.

2、Dry material for tundish:dry ramming ,used for tundish working lining

3、Coating mass for tundish: artificial coating for the tundish work linling

4、Castable for tundish permanent lining: used for casting of the permanent lining of the tundish.

主要理化指标:

| Brand/ Index | MgO(%) | CaO(%) | SiO2(%) | B.D (g/cm3) | |

|---|---|---|---|---|---|

| Spray mass for tundish | HTPL-1 | ≥80 | ≤3.0 | ≤9.0 | ≥1.3 |

| Dry material for tundish | HTGD-1 | ≥64 | 18-23 | ≥2.2 | |

| Coating mass for tundish | HTTM-1 | ≥64 | ≤30 | ≥1.5 | |

Castable for tundish permanent lining | HTFJ-1 | ≤60 | ≤2.2 | ||

| The above specification indexes can be adjusted according to customer’s requirements | |||||