Aluminum-Magnesia Carbon brick、Magnesia-Aluminum Carbon brick for Ladle

Production Process:

High alumina bauxite, corundum, high-quality fused magnesia and natural flake graphite as the main raw materials, organic matter as the binder, reasonable addition of antioxidants, by mixing, high pressure forming, heat treatment process High bulk density, low apparent porosity, excellent thermal stability and erosion resistance.

Main application:

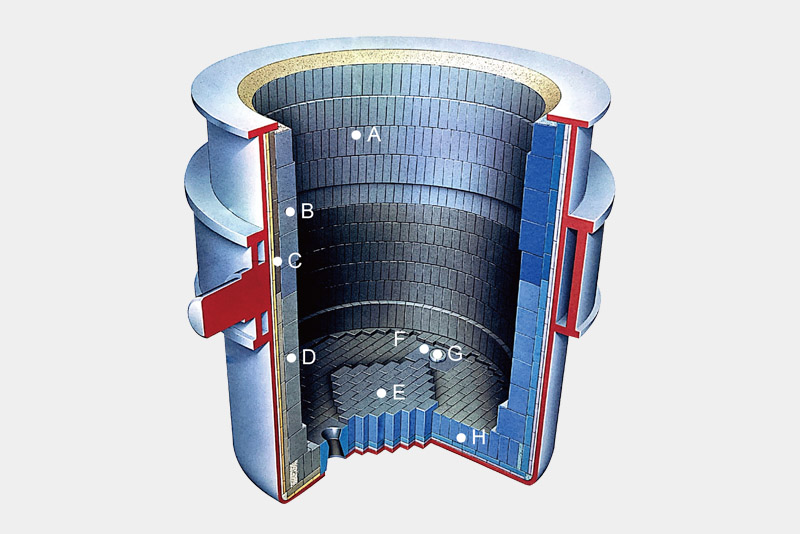

The lade work lining the bottom of the ladle, the side wall and the masonry of the transition zone.

主要理化指标:

| Brand/ Index | MgO(%) | Al2O3(%) | F/C(%) | B.D (g/cm3) | A.P(%) | Cold crushing strengt h(MPa)C.C.S |

|---|---|---|---|---|---|---|

| HLAMC-65 | ≥10 | ≥65 | ≥6 | ≥2.95 | ≤8 | ≥50 |

| HLAMC-70 | ≥8 | ≥70 | ≥6 | ≥3.00 | ≤8 | ≥50 |

| HLMAC-25 | ≥55 | ≥25 | ≥8 | ≥2.96 | ≤6 | ≥45 |

| HLMAC-10 | ≤70 | ≥10 | ≤8 | ≥2.98 | ≤6 | ≤45 |

| The above specification indexes can be adjusted according to customer’s requirements | ||||||