Unshaped Refractories for EAF

Production Process:

1、Gunning mass of EAF: high-quality magnesia or forsterite as the main raw material, plus a variety of composite binders, additives are mixed and made

2、Ramming mass of EAF bottom: high-purity synthetic dolomite sand and high-purity magnesia as the main raw material, the appropriate addition of bonding agent is prepared by mixing.

3、Hot repairing mass of EAF slope: synthetic dolomite sand as the main raw material, adding binder and sintering agent by mixing.

The main purpose:

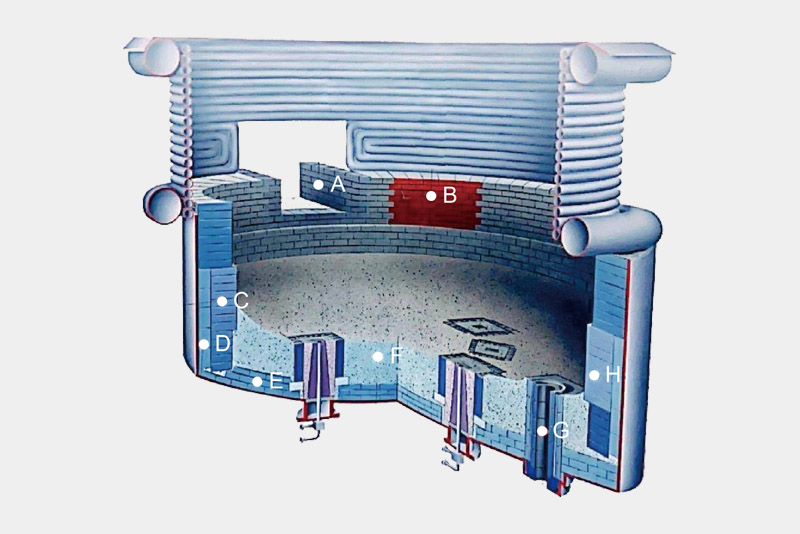

1、Gunning mass of EAF: used for spraying the EAF wall

2、Ramming mass of EAF bottom: used for beating of EAF bottom

3、Hot repairing mass of EAF slope: used for hot repair of EAF slope

主要理化指标:

Product Name | Brand/ Index | MgO(%) | Fe2O3(%) | SiO2(%) | CaO(%) | B.D (g/cm3) |

|---|---|---|---|---|---|---|

Gunning mass of EAF | HEMPL-1 | ≥87 | ≤2 | ≤6 | 4-6 | ≥2.5 |

| HEGPL-1 | ≥66 | 4-6 | 22-26 | ≤2 | ≥2.4 | |

| Ramming mass of EAF bottom | HEDL-1 | ≥80 | 3-6 | ≤5 | 5-10 | ≥2.0 |

| HEDL-2 | ≥76 | 3-6 | ≥1.6 | 12-18 | ≥2.1 | |

| Hot repairing mass of EAF slope | HEXB-1 | ≥50 | 4-8 | 30-40 | ≥2.2 | |

| The above specification indexes can be adjusted according to customer’s requirements | ||||||